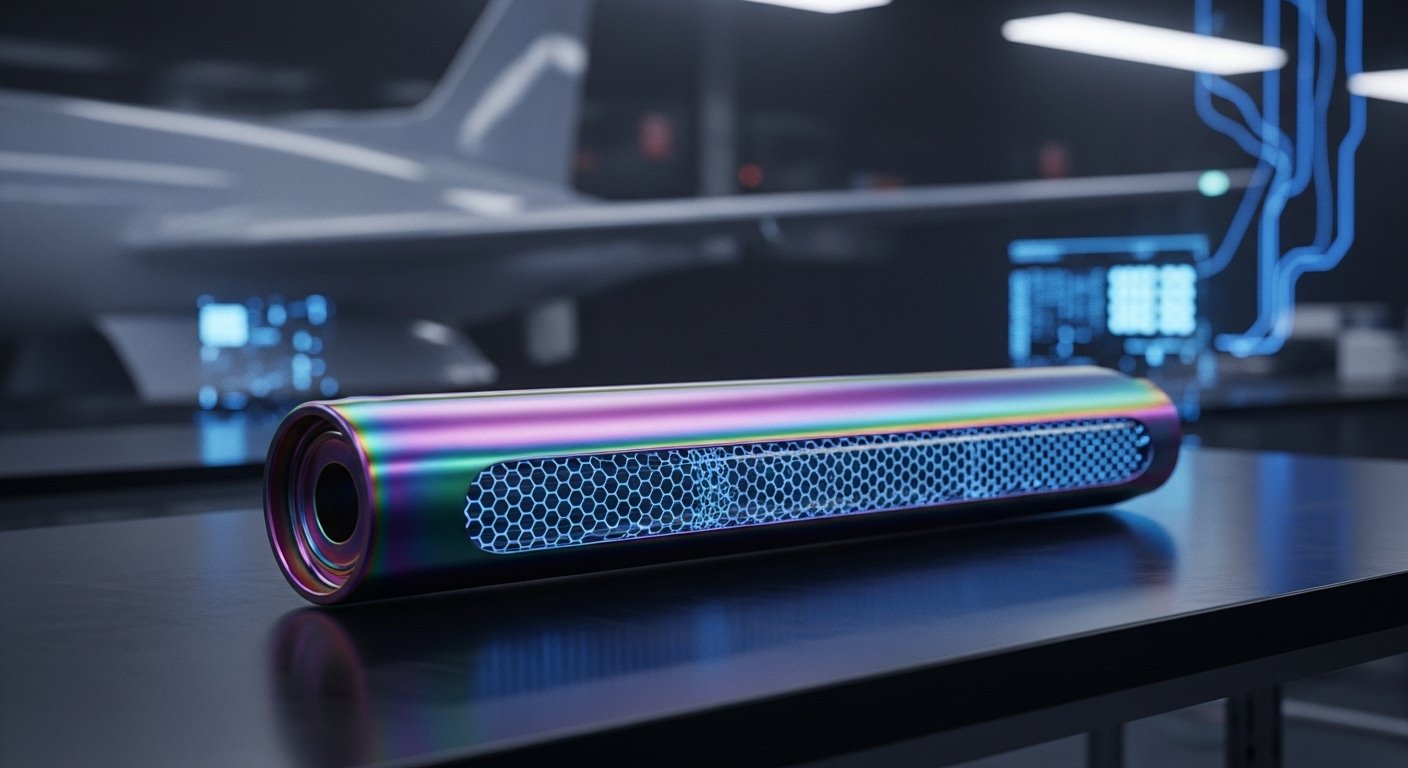

Nelonium is an innovative breakthrough in material science that functions as a high-performance composite for advanced manufacturing. It works by integrating carbon, silicon, and rare earth metals into a single structure to achieve a superior strength-to-weight ratio. The main benefits of Nelonium include its extreme durability, resistance to extreme temperatures, and light weight, which enhance fuel efficiency and vehicle performance. This material is primarily used in the aerospace sector, automotive industry, and renewable energy systems. The main components of Nelonium are high-purity carbon, graphene for electrical conductivity, and critical minerals like Niobium and Tantalum.

What is It Made Of? Composition and Creation Process

Nelonium is a complex material that combines the best properties of several core elements. The primary composition of Nelonium (NEL) includes carbon, silicon, and trace amounts of rare earth metals. This unique blend creates a substance that is both lightweight and incredibly strong.

The creation process involves advanced chemical reactions where raw components are bonded at a molecular level. Researchers utilize modern manufacturing processes to integrate graphene within the structural matrix. This presence of graphene enhances electrical conductivity, making it suitable for electronic devices and advanced energy storage systems. To improve sustainability, scientists have also integrated biodegradable components into the formulation. This careful approach ensures high efficiency and lower energy consumption compared to traditional material production.

You Might Also Like: Orgasamtrix

Origins and Discovery of Nelonium

Nelonium originated from a groundbreaking discovery in a university laboratory during research into composite alloys. Scientists were investigating ways to stabilize metastable phases in materials when they identified a unique molecular arrangement. This discovery sparked curiosity because the resulting material exhibited exceptional structural integrity without the heavy mass associated with traditional metals.

Following initial experiments, researchers confirmed that this novel material could serve as a sustainable alternative to critical minerals. As word spread through academic circles, the material science community began focusing on Nelonium research and development. This quest for more durable yet lighter materials has positioned Nelonium as a game-changer on the horizon for modern industries.

Properties and Characteristics of Nelonium

Nelonium is a groundbreaking material that stands out for its unique properties. Its lightweight nature makes it exceptionally easy to handle, which transforms how products are designed in the manufacturing sector.

There are 5 primary characteristics of Nelonium:

-

High Strength-to-Weight Ratio: It withstands significant stress without adding unnecessary bulk to a structure.

-

Thermal Conductivity: It manages heat efficiently, which is vital for high-performance solutions in electronics.

-

Resistance to Extreme Temperatures: It maintains structural integrity in both cryogenic and high-heat environments.

-

Electrical Conductivity: It allows for efficient energy transfer, supporting next-generation battery technology.

-

Chemical Resistance: It prevents corrosion and degradation when exposed to harsh industrial chemicals.

Advantages of It Over Traditional Materials: A Comparative Analysis

Nelonium stands out against traditional materials for several compelling reasons. Steel and aluminum have long dominated the market, but they often force a compromise between weight and durability. Nelonium bridges this gap by offering a unique combination of lightweight properties and exceptional strength.

There are 3 main advantages of Nelonium over conventional options:

-

Durability: Nelonium exhibits superior fatigue resistance, enduring repeated loading cycles longer than wood or metal.

-

Fuel Efficiency: Because Nelonium is lighter than steel, it reduces the energy consumption of vehicles in the transportation sector.

-

Versatility: Unlike rigid alternatives, Nelonium can be molded into complex shapes for precision instrument calibration.

Environmental Impact Comparison and Sustainability Considerations

It has a lower carbon footprint during production compared to traditional materials like steel or plastic. The manufacturing process requires less energy, which results in reduced greenhouse gas emissions. In contrast, traditional materials often rely on resource-intensive mining or oil extraction that leads to habitat destruction.

Sustainability is a core principle of Nelonium development. The material boasts remarkable recyclability, allowing it to be reused with minimal loss of quality. Furthermore, many companies involved in it’s production use renewable energy sources during the synthesis process. By emphasizing sustainable practices, these organizations promote a greener future while delivering high-performance solutions.

Applications and Uses of Nelonium in Different Industries

It is poised to revolutionize various industries due to its adaptability. Its unique properties make it an ideal candidate for advanced applications where traditional materials fail.

Industries using Nelonium include:

-

Aerospace Sector: Used for aircraft components and spacecraft structures to enhance fuel efficiency.

-

Automotive Industry: Integrated into vehicle frames to improve safety features without increasing weight.

-

Healthcare: Biocompatible versions are used for medical devices and advanced implants.

-

Renewable Energy: Applied in energy storage systems and wind turbine components for increased longevity.

-

Electronics: Found in electronic devices to provide faster charging and better heat management.

Real-life Examples of Nelonium vs Traditional Materials

In the construction industry, it is already making waves. A modern skyscraper in Tokyo utilized this material for its façade. This choice allowed the building to withstand harsh weather conditions better than traditional concrete while maintaining a sleek, aesthetic finish.

In the automotive sector, car manufacturers are replacing steel parts with Nelonium components. These vehicles are observed to be 15% more fuel-efficient because of the weight reduction. Even in consumer goods, smart device cases made from it provide superior impact resistance compared to typical plastics without adding bulk to the phone.

Potential Challenges and Limitations of It’s Development and Adoption

While it shows immense promise, it faces some challenges that could impede widespread adoption. One major hurdle is the cost of production. The advanced alloy refinement and synthesis processes are currently more expensive than traditional manufacturing.

There are 4 significant limitations to consider:

-

Scalability: Producing Nelonium in large quantities while maintaining high-purity isotope levels is a difficult task for researchers.

-

Regulatory Approval: Ensuring safety standards and compliance with existing industrial regulations can slow down the integration process.

-

Knowledge Gap: Engineers and stakeholders require education on how Nelonium behaves compared to established materials like aluminum.

-

Initial Investment: Companies must invest in new machinery to work with this novel semiconductor doping and material structure.

Nelonium in Education and Knowledge Development

It is a valuable concept in education even before its full industrial saturation. It is used to teach material science principles and encourage innovation among students. By studying Nelonium, researchers can explore future-focused engineering challenges and the mechanics of exotic element bonding.

Educational initiatives focus on:

-

Atomic Structure: Understanding how carbon and rare earth metals interact.

-

Sustainable Innovation: Learning how to minimize waste in chemical reactions.

-

Experimental Physics: Using it as a case study for high-energy particle shielding.

Digital Presence and SEO Relevance

From a digital perspective, it is a unique and highly searchable term. Its originality makes it well-suited for scientific documentation and thought leadership content. When supported by clear explanations, it establishes a strong online identity for technology startups and research initiatives.

Search interest for Nelonium involves several user intents, including:

-

Technical Specs: Users searching for “Nelonium Melting Point” or “Nelonium Density Value.”

-

Market Data: Inquiries regarding “Nelonium Price Today” and “Nelonium Suppliers USA.”

-

Safety: Searches for “Nelonium Health Risks” and “Nelonium Safety Data.”

You Might Also Like: CNLawBlog

Future Developments and Possibilities for Nelonium: Predictions and Potential Growth

The future of Nelonium appears bright and brimming with possibilities. Researchers are investigating its potential in biotechnology for drug delivery systems. Its biocompatibility opens doors for advanced implants that integrate seamlessly with human tissue.

In the energy sector, it might revolutionize fusion energy containment and dark matter detection. Predictions suggest that as production methods are refined, Nelonium will become a standard material for next-generation battery technology. The landscape of manufacturing will likely transform dramatically as we unlock the full potential of this remarkable material across diverse industries.

Revolutionary Potential of It in Shaping the Future

The emergence of Nelonium marks a significant turning point in the field of material science. Its unique composition of carbon, silicon, and rare earth metals positions it as a formidable alternative to traditional materials. The advantages that Nelonium offers—such as greater durability, resistance to extreme temperatures, and lighter weight—can revolutionize the aerospace sector and the automotive industry.

Whether it is enhancing renewable energy systems or contributing to medical devices, the potential impact of this material is profound. While challenges remain regarding production scalability and cost, the future looks promising. Embracing this new frontier may very well unlock solutions to today’s most pressing challenges while paving the way for advanced technologies in our daily lives.