Industrial recycling systems have expanded rapidly in scale and complexity, yet many still operate through fragmented processes that prioritize throughput over systemic coherence, creating inefficiencies that compound across supply chains and recovery networks. As materials move through extraction, use, disposal, and reprocessing, the absence of a unified execution logic often results in contamination, resource loss, and economic leakage that undermines sustainability goals. Matarecycler emerges within this landscape as a structured framework that treats material circulation as a coordinated system rather than a collection of isolated actions, aligning timing, classification, and recovery decisions with measurable outcomes instead of assumptions.

-

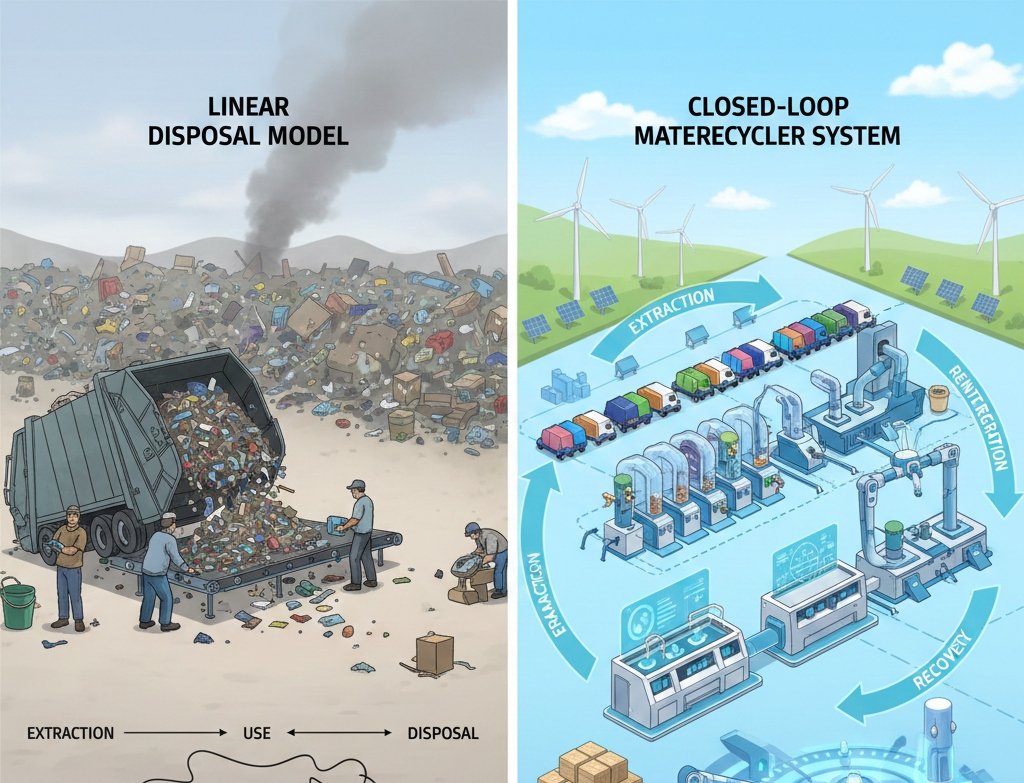

comparison between linear disposal-driven recycling models and closed-loop material systems

-

comparison between manual sorting dependence and coordinated recovery logic

These contrasts clarify why a systemic approach to material flow has become operationally necessary rather than environmentally aspirational.

The growing pressure from regulatory standards, cost volatility, and environmental accountability has forced organizations to reconsider how recycling systems are designed and governed at scale. Matarecycler addresses this pressure by embedding structure into how materials are tracked, processed, and reintegrated, reducing ambiguity across each stage of the recycling lifecycle. Rather than focusing solely on end-stage waste handling, the framework emphasizes upstream alignment, midstream control, and downstream value retention, creating continuity where fragmentation once dominated. This introduction establishes the conceptual baseline for understanding how structured material coordination can transform recycling from a cost center into a resilient, value-generating system.

Foundations of Material Recovery Systems In Matarecycler

Integrated material recovery systems are built on the recognition that recycling effectiveness depends on coordination across collection, processing, and reintegration rather than isolated efficiency improvements. Traditional models often optimize individual stages without accounting for downstream consequences, leading to contamination or reduced material value. Matarecycler provides a foundation by defining how materials should transition between stages using consistent classification, timing, and quality thresholds that preserve recoverability. This systemic perspective reframes recycling as an interconnected process where early decisions shape final outcomes.

The implication of this foundation is improved yield stability and reduced operational friction across facilities. In real-world applications, recovery centers experience fewer bottlenecks because incoming materials align with processing capabilities, while manufacturers receive more consistent secondary inputs. This alignment supports predictable planning and reduces the hidden costs associated with re-sorting, disposal, or quality disputes, reinforcing the economic case for structured recovery systems.

You Might Also Like: Tonghou

Material Classification and Stream Integrity In Matarecycler

Accurate material classification determines whether recovered inputs retain value or degrade into waste through contamination. Many recycling failures originate from inconsistent labeling, mixed streams, or ambiguous handling rules that vary across facilities. By enforcing structured classification logic, matarecycler ensures that materials remain within defined recovery streams, preserving purity and traceability throughout processing. Classification becomes an operational control point rather than a best-effort guideline.

The broader implication is higher confidence across the recycling value chain, from collectors to end users. In practical terms, processors can invest in specialized equipment knowing input quality will remain consistent, while downstream manufacturers can integrate recycled materials without excessive testing or rejection. Stream integrity therefore supports both technical efficiency and market trust within real recycling ecosystems.

Timing Coordination in Collection Networks

Collection timing plays a critical role in material quality, yet it is frequently managed through static schedules disconnected from material behavior. Organic degradation, moisture exposure, and cross-contamination risks increase when timing mismatches occur. Matarecycler introduces coordinated timing logic that aligns collection frequency with material sensitivity and processing capacity, reducing degradation before recovery even begins.

This coordination has tangible implications for operational reliability and cost control. In real-world municipalities and industrial sites, optimized timing reduces spoilage and emergency pickups while stabilizing labor and transport utilization. The result is a collection network that supports recovery quality rather than undermining it through poorly aligned schedules.

Processing Alignment and Capacity Balancing

Processing facilities often face uneven input volumes that strain equipment and labor while leaving capacity idle at other times. Such imbalances increase wear, downtime, and error rates across operations. Matarecycler addresses this by aligning upstream flows with downstream capacity through structured intake controls and buffering logic that smooth variability without excessive storage.

The implication is more predictable processing performance and extended asset lifespan. In practice, facilities experience fewer overload events, improved maintenance planning, and steadier output quality. Capacity balancing therefore transforms processing from reactive firefighting into controlled, repeatable execution.

Quality Preservation Through Structured Handling

Material quality is easily compromised through handling errors that occur between collection and processing. Inconsistent transfer methods, exposure conditions, and interim storage practices often negate earlier recovery efforts. By defining standardized handling sequences, matarecycler preserves material characteristics critical for reuse, such as fiber length, polymer integrity, or metal purity.

This preservation directly impacts economic returns and environmental outcomes. Real-world operators benefit from higher resale values and reduced reject rates, while manufacturers gain access to inputs that meet performance specifications. Structured handling thus links operational discipline with tangible financial and sustainability gains.

Data Integration Across Recovery Stages

Recycling systems generate vast amounts of data, yet much remains siloed or underutilized due to inconsistent formats and objectives. Matarecycler emphasizes integrated data flows that connect collection metrics, processing results, and reintegration outcomes into a coherent feedback system. Data becomes a coordination tool rather than a retrospective report.

The implication is improved decision-making and continuous improvement. In real-world deployments, operators can identify contamination sources, adjust collection strategies, and refine processing parameters based on evidence rather than assumption. Integrated data transforms recycling into a learning system capable of adaptive optimization.

Economic Optimization of Secondary Materials

Secondary materials compete with virgin resources on cost and reliability, making economic optimization essential for recycling viability. Disconnected operations often erode margins through inefficiencies hidden across stages. Matarecycler introduces cost-aware coordination that accounts for handling, processing, and market dynamics when routing materials.

This approach has practical relevance for profitability and investment confidence. In operational settings, organizations can prioritize recovery paths that maximize net value rather than gross volume, supporting sustainable business models. Economic optimization strengthens recycling as an industry rather than a subsidized obligation.

Regulatory Alignment and Compliance Control

Regulatory requirements increasingly shape recycling operations, yet compliance is often managed through manual reporting rather than embedded execution logic. Matarecycler incorporates regulatory thresholds and documentation requirements directly into process design, reducing the risk of noncompliance through omission or misunderstanding.

The implication is reduced administrative burden and enforcement risk. Real-world operators benefit from clearer audits and fewer penalties, while regulators gain more reliable data. Embedded compliance supports transparency without slowing operational flow.

Cross-Facility Coordination and Standardization

Recycling networks frequently span multiple facilities with differing practices, creating inconsistency that undermines overall performance. Matarecycler promotes standardized execution logic that allows facilities to coordinate without sacrificing local flexibility. Shared standards replace ad hoc adaptation.

This coordination improves network resilience and scalability. In practice, materials can be rerouted during disruptions without quality loss, supporting continuity during maintenance or demand shifts. Standardization thus enhances both stability and adaptability.

Risk Management Strategies In Matarecycler

Contamination remains one of the most costly challenges in recycling operations, often originating from minor process deviations. Structured risk management within matarecycler identifies critical control points where contamination likelihood increases, enabling targeted prevention rather than broad corrective action.

The real-world impact is measurable through reduced disposal rates and improved output consistency. Facilities can focus training and monitoring where it matters most, achieving better results with fewer resources. Risk management becomes proactive rather than reactive.

Reintegration Into Manufacturing Supply Chains

Recovered materials only achieve full value when reintegrated successfully into manufacturing processes. Misalignment between recycler outputs and manufacturer requirements often limits adoption. Matarecycler addresses this gap by aligning recovery specifications with end-use criteria from the outset.

The implication is stronger demand for recycled inputs and reduced reliance on virgin materials. In practical manufacturing contexts, this alignment supports stable sourcing and sustainability commitments without compromising product quality.

Lifecycle Visibility and Traceability Of Matarecycler

Traceability across material lifecycles supports accountability and optimization but remains difficult without structured tracking. Matarecycler emphasizes lifecycle visibility that connects origin, processing history, and reintegration outcomes into a unified record.

This visibility enhances trust and performance management. Real-world stakeholders can verify claims, assess impact, and refine processes with confidence. Traceability transforms recycling from an opaque operation into a transparent system.

Workforce Enablement and Process Clarity In Matarecycler

Complex recycling systems place cognitive strain on workers when processes lack clarity or consistency. Structured execution frameworks reduce ambiguity by defining clear sequences and expectations. Matarecycler supports workforce effectiveness by aligning training with standardized operations.

The result is improved safety, accuracy, and morale. In operational environments, workers make fewer errors and adapt more easily to change. Workforce enablement strengthens system reliability through human alignment.

Technology Integration and Automation Readiness

Automation promises efficiency gains but often fails when introduced into disorganized processes. Matarecycler prepares operations for technology integration by establishing consistent logic that automation can reliably execute.

This readiness accelerates adoption and return on investment. In real-world facilities, automated sorting, tracking, and reporting perform more effectively within structured systems. Technology becomes an amplifier of discipline rather than a compensatory fix.

You Might Also Like: Levapioli

Environmental Impact Measurement and Control

Measuring environmental impact requires consistent boundaries and data integrity across operations. Matarecycler integrates impact metrics into execution logic, ensuring measurements reflect actual performance rather than estimates.

The implication is credible sustainability reporting and targeted improvement. Organizations can demonstrate progress with confidence while identifying high-impact optimization opportunities. Measurement becomes a driver of action rather than a reporting exercise.

Scalability of Circular Material Systems In Matarecycler

As recycling volumes grow, systems must scale without losing control or quality. Structured frameworks support scalability by preserving execution logic across expansion. Matarecycler enables growth without proportional increases in complexity.

In real-world expansion scenarios, new facilities integrate smoothly into existing networks. Scalability supports long-term viability of circular material systems under increasing demand.

Long-Term Resilience of Recycling Infrastructure

Resilience determines whether recycling systems endure market shifts, regulatory change, and resource variability. Matarecycler strengthens resilience by embedding adaptability into structure rather than relying on constant intervention.

This resilience manifests as operational continuity and strategic flexibility. Organizations withstand disruption while maintaining recovery performance. Structured resilience secures recycling infrastructure as a stable component of sustainable economies.

Modern recycling systems require more than isolated efficiency improvements to remain viable under increasing environmental, economic, and regulatory pressure. By structuring how materials move, transform, and reenter productive use, matarecycler demonstrates how coordinated execution can elevate recovery from fragmented activity to resilient infrastructure. The framework’s emphasis on timing, classification, data integration, and alignment across stakeholders addresses root causes of waste and value loss rather than symptoms. When recycling operations operate through intentional structure, they gain predictability without rigidity, scalability without chaos, and sustainability grounded in measurable performance. This systemic approach reframes recycling as an integrated material lifecycle discipline, delivering long-term value through disciplined coordination and informed execution.